As a company, we want to make sustainable decisions and developments to help prevent global warming from increasing even further. This is important to us.

We know that the operation of cleanrooms is energy-intensive. However, we have not yet been able to precisely quantify the environmental impact caused, for example, by the extraction of the raw materials we use. We wanted to find out more about this.

In order to improve our sustainability in a targeted manner, we had a life cycle assessment (LCA) drawn up for our products in accordance with ISO 14040. This analysis method aims to comprehensively quantify the potential environmental impact and resource consumption of a product over its entire life cycle. A so-called cradle-to-crave analysis was carried out, which considers the CO2 emissions of our products from the extraction of raw materials through production and use to disposal or recycling. In addition, we used the CML2001 method to examine a range of environmental impacts such as the greenhouse effect, ozone formation and toxicity.

The study provides us with valuable insights for identifying potential improvements and optimizing product design with regard to environmental performance. If, for example, the CO2 emissions of cleanrooms over the entire life cycle are considered from the many criteria, the results are more than clear:

95% of CO2 emissions occur during the use phase

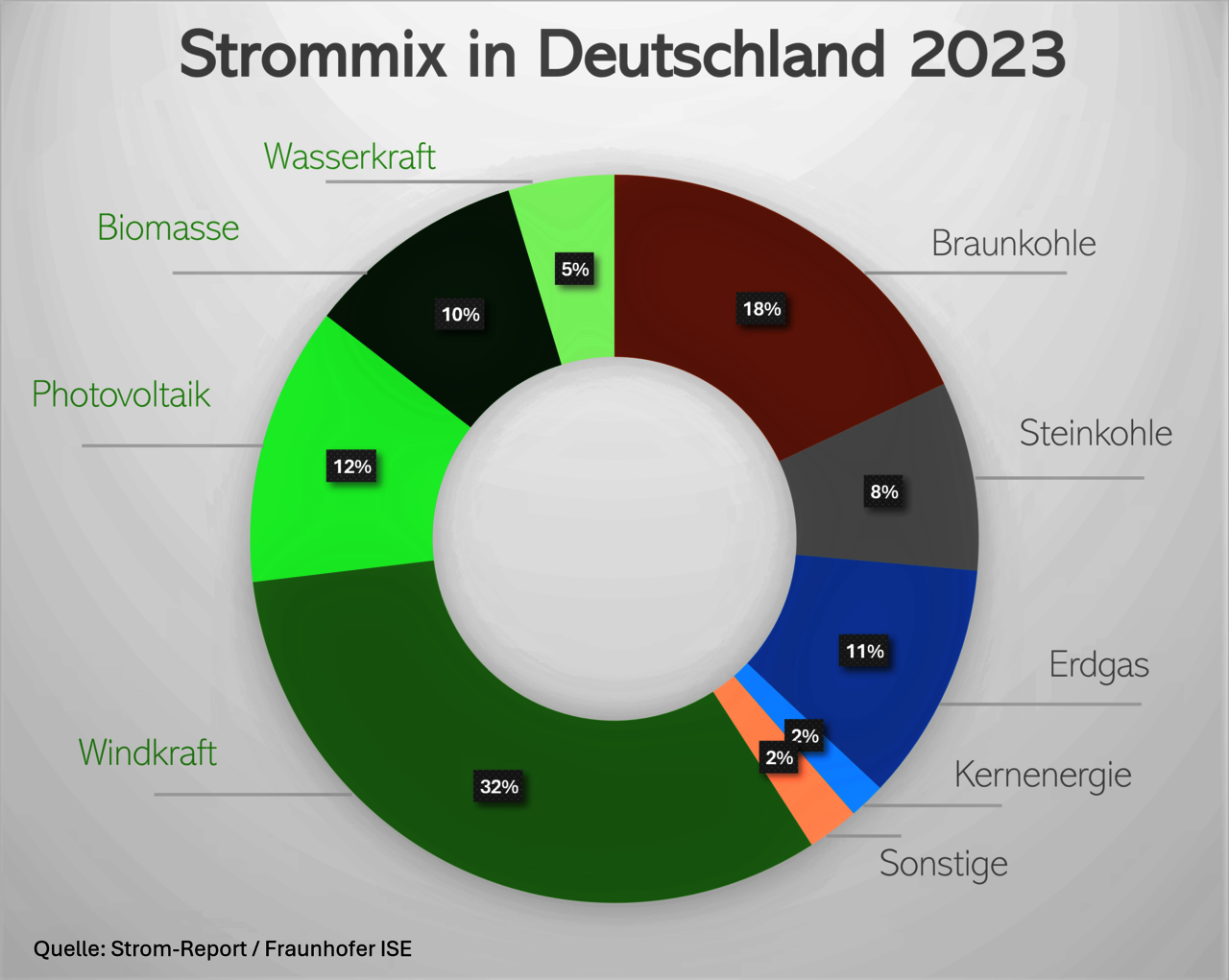

Electricity consumption, which occurs continuously during the operation of a cleanroom, therefore accounts for by far the largest proportion of emissions. In contrast, the energy required for the extraction of raw materials and the production of a cleanroom system only plays a subordinate role in the life cycle assessment. (taking into account the German electricity mix)

The largest energy consumers in a cleanroom are fan filter units (FFUs) and air conditioning systems that run continuously. The most important factor for the sustainability of cleanroom systems is therefore more energy-efficient operation, which can be achieved through various measures, such as the use of energy-efficient FFUs and air conditioning systems or the implementation of intelligent control systems.

In addition, the study recommends the increased use of alternative building materials made from renewable or recycled materials to improve the environmental compatibility of the raw materials used.

We are actively working on this. Based on the results, we have already initiated and further developed a number of measures to improve the environmental performance of our products. This will not happen overnight, but we are confident that we will soon be able to present more sustainable innovations.