Your safe cleanroom workstation - Laminar Flow Cabinets and Hoods

Our CleanProCel Laminar Flow Cabinets and Laminar Flow Hoods use innovative filter technology and optimised airflow to provide a safe environment for your cleanroom workstation. The workbenches and table tops offer maximum product and personal protection in a minimum of space and are particularly suitable for sensitive production and measurement tasks as a defined clean air area. Designed for critical cleanroom work areas, they use state-of-the-art laminar flow technology to create a uniform airflow that effectively minimises particles and contamination. Use Flow Boxes as a quick solution for a protected process or to selectively increase the cleanroom class within your cleanroom.

Laminar-Flow-Cabinet in Aluminium 1330 mm

Product details

Laminar-Flow-Cabinet in Aluminium 1990 mm

Product details

Laminar-Flow-Hood in Melamine 1260 mm

Product details

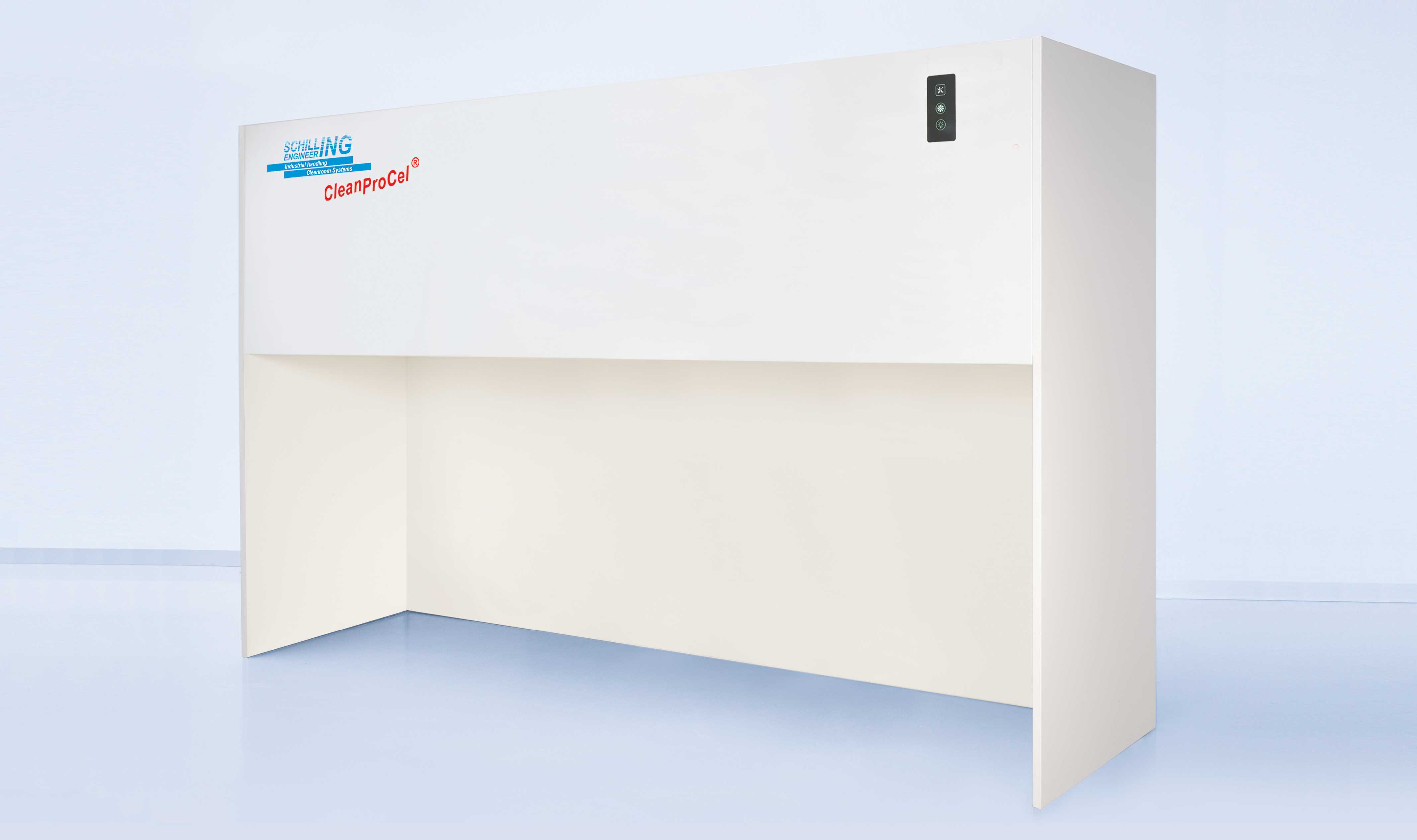

Laminar-Flow-Hood in Melamine 1870 mm

Product detailsAluminium Laminar-Flow-Cabinet

Our Laminar-Flow-Cabinet convince with a compact design that can be modified according to your requirements. With cleanroom-compatible aluminum profiles and glass side panels, the laminar flow workbench can be flexibly adapted to your requirements in terms of size and equipment. It meets all requirements of ISO cleanroom class 5 as well as GMP class A and B. The laminar flow workbench is therefore optimally suited for your GMP applications. Especially in the areas of pharmaceutical production or analytical and chemical processes, the use of a laminar flow cabinet made of aluminum is of high user comfort.

Melamine Laminar-Flow-Hood

Our compact Laminar Flow Hoods in melamine are particularly practical and can be used immediately as table centrepieces. They provide a controlled work surface for applications that require a sterile work area, while preventing contamination through a constant filtered air flow across the work area. With the Flow Box providing vertical laminar flow, you can quickly achieve ambient air that meets ISO 5 cleanroom class requirements. Of course, we also supply the matching cleanroom tables if required.

A filter fan unit is integrated into the ceiling of the laminar flow cabinets and hoods. Ambient air is drawn in via a pre-filter and then passes vertically into the work area as a laminar airflow through a high performance U15 filter. This laminar airflow moves continuously across the work surface, removing airborne particles and ensuring a contamination-free working environment.

Laminar flow cabinets and hoods are the right choice when a precise and controlled working environment is required. A laminar flow solution is particularly suitable for sensitive processes or precision work, as it offers precise control of airflow and effective particle removal. In addition, cleanroom workstations can selectively increase the cleanroom class of existing cleanrooms, making them an ideal solution for applications where the highest standards of cleanliness are required.

The difference between our aluminium cleanroom cabinets and our melamine laminar flow hoods is in the material, design and application.

The cabinets consist of an aluminium frame with glass walls into which the FFUs and work surface are permanently integrated. The height of the cabinet can be selected for sitting or standing work. They are also suitable for applications requiring GMP Class A and B specifications.

The melamine flow hoods are practical laminar flow attachments with integrated FFUs that can be placed on your benches. We are happy to supply matching cleanroom benches, including height adjustable versions.