Injection moulding machine attachments: Protect and improve processes

Injection moulding machines are usually used for the production of plastics in medical technology or for pharmaceutical packaging. Certain requirements such as the cleanroom box apply to this process so that particle-free production is guaranteed. The manufacturing environment must be as clean as possible. This laminar flow module safeguards your production environment by creating a controlled laminar flow within the machine. The laminar flow box reduces the particle concentration to a minimum and prevents the contamination of sensitive products.

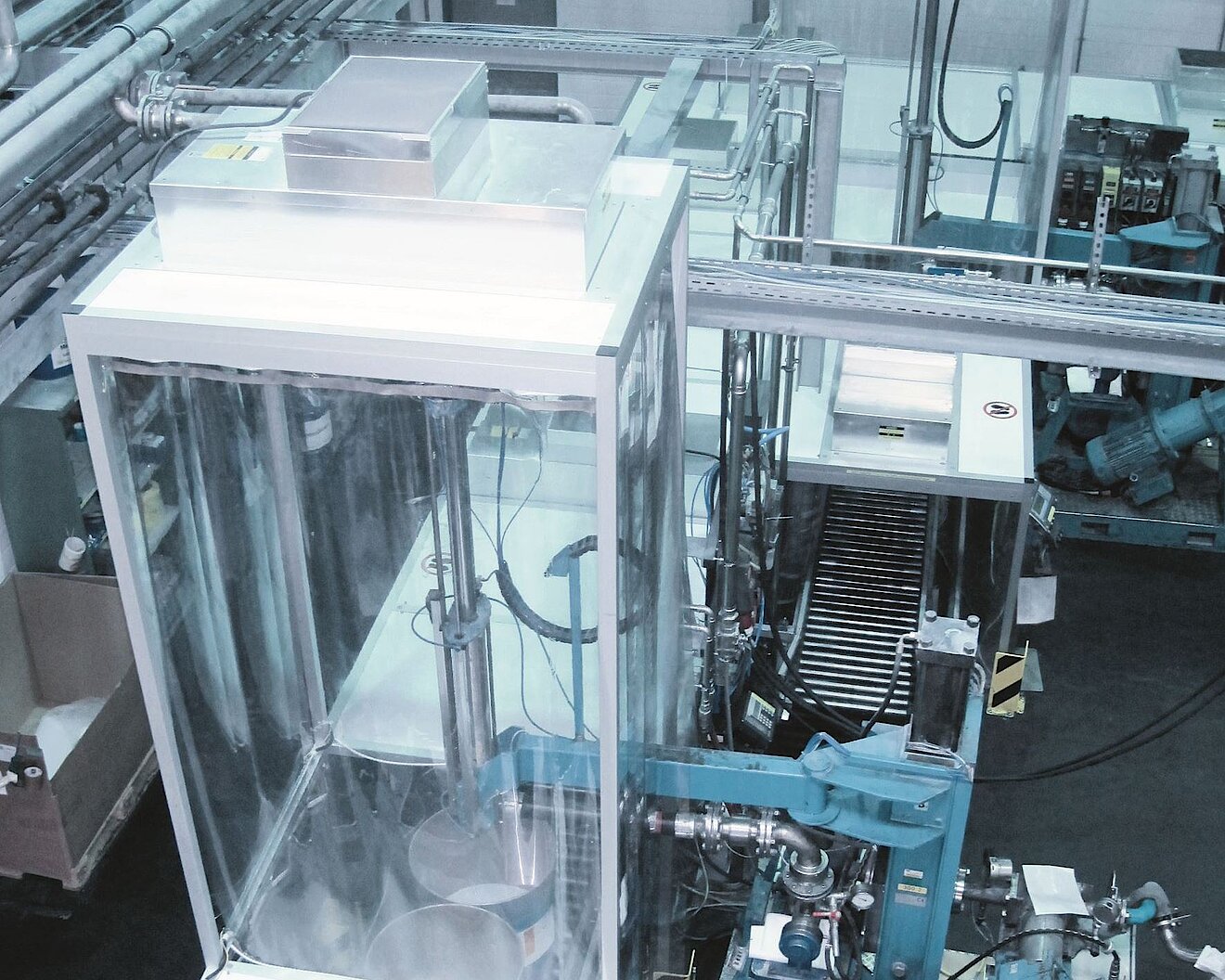

Enclosures: Check and control laminar flow

For production machines as well as for the general production environment, smaller cleanroom enclosures or laminar flow modules are sometimes sufficient to control the air flow and particle distribution within the process. The enclosure spatially delimits defined clean air areas and ensures that you can carry out your work processes without hesitation. Whether enclosed with PVC film curtains or solid walls - we secure your production with defined clean air flows.