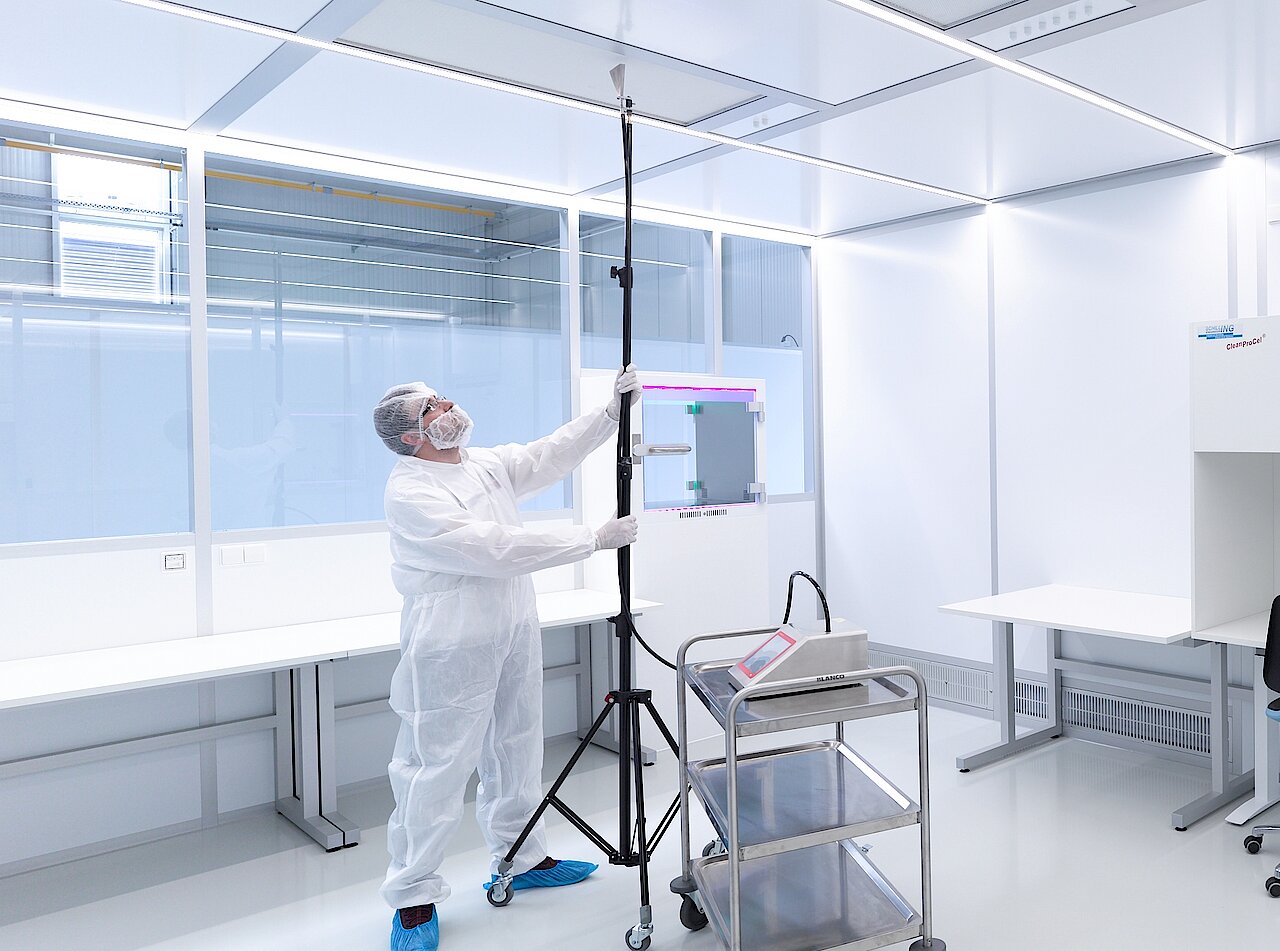

Not only can we help you with your initial cleanroom qualification, but we can also carry out any necessary re-qualifications. Our experienced service engineers provide professional support, carry out particle measurements in the cleanroom and other tests, and record the results. They can also provide fast, reliable maintenance and replacement of filter systems.

Qualification

Cleanroom qualification ensures that the cleanroom meets its specific requirements. Qualification tests are carried out by our experienced service engineers in accordance with DIN EN ISO 14644 and EU GMP guidelines and recorded in detailed GMP documentation. All work steps, test procedures and readings are traceable for external inspection bodies.

Requalification

Re-qualification is carried out to demonstrate that the cleanroom facility is still in a qualified state after modifications. Requalification is also required as part of periodic revalidation. Particle measurements for room qualification must be repeated every 6 or 12 months, depending on the zone.

Cleanroom qualification is a procedure for checking and documenting compliance with cleanroom classes in accordance with specific standards. The standards specify the requirements for particle concentration, air exchange rate, temperature, humidity and other parameters in a cleanroom. The most important standards for cleanroom qualification are ISO 14644-3, VDI 2083 and the GMP Annex 1 guideline.

The aim of a cleanroom qualification is to ensure that the cleanroom is suitable for the intended purpose and guarantees the desired quality of the products or processes. The qualification is documented proof that the cleanroom system is planned, built, installed and operated in accordance with user requirements and the applicable regulations.

The requalification of a cleanroom is carried out to check its performance and compliance with the specified standards for the cleanroom class. Requalification must be carried out at regular intervals to ensure that the cleanroom fulfills its function and does not cause contamination. The frequency of requalification depends on various factors, such as the type of activities in the cleanroom, the requirements of customers or authorities, the results of routine monitoring and changes to the system or equipment. We recommend that requalification is carried out at least once a year.

In ISO, it is usually sufficient to carry out and record a qualification in accordance with ISO 14644-3. The resulting qualification protocol then serves as documented proof.

In the GMP area, the requirements are more stringent and the result of each test should be documented according to a predetermined procedure and released for the next step:

DQ: Design Qualification = Design Qualification

IQ: Installation Qualification = Installation Qualification

OQ: Operational Qualification = Functional Qualification

PQ: Performance Qualification = Performance Qualification

The classification of a cleanroom into a specific class is based on precise particle measurements in the cleanroom, which record the concentration of particles in the air. These measurements are typically carried out using a laser particle counter to ensure that the number of particles in the air does not exceed the limits set for the relevant ISO or GMP classification. By strictly controlling and minimising these particles, a cleanroom will maintain its classification, which is essential for maintaining the required standards of cleanliness in sensitive production and research environments.