A controlled environment is essential for the manufacture of sensitive products. As every square meter of cleanroom is associated with high costs, our laminar flow modules offer an efficient solution. They make it possible to isolate individual production processes through targeted machine enclosures and thus reduce the required cleanroom area to a minimum. These modules generate a laminar flow, i.e. a uniform air flow that effectively and specifically removes harmful particles during production.

Machine attachments for injection molding

The production of plastics for medical devices and pharmaceutical packaging must comply with strict legal requirements. Specifications and ensuring contamination-free production are essential. Our machine attachments, the CleanFlowCell®, offer a revolutionary solution for preventing airborne contaminants such as viruses, bacteria, dust and abrasion particles during the injection molding process. The laminar flow module can be flexibly mounted on all standard injection molding machines and allows you to easily change tools by moving them sideways. Rely on technology that meets the strictest cleanliness standards and optimize your production processes.

Customized machine enclosures

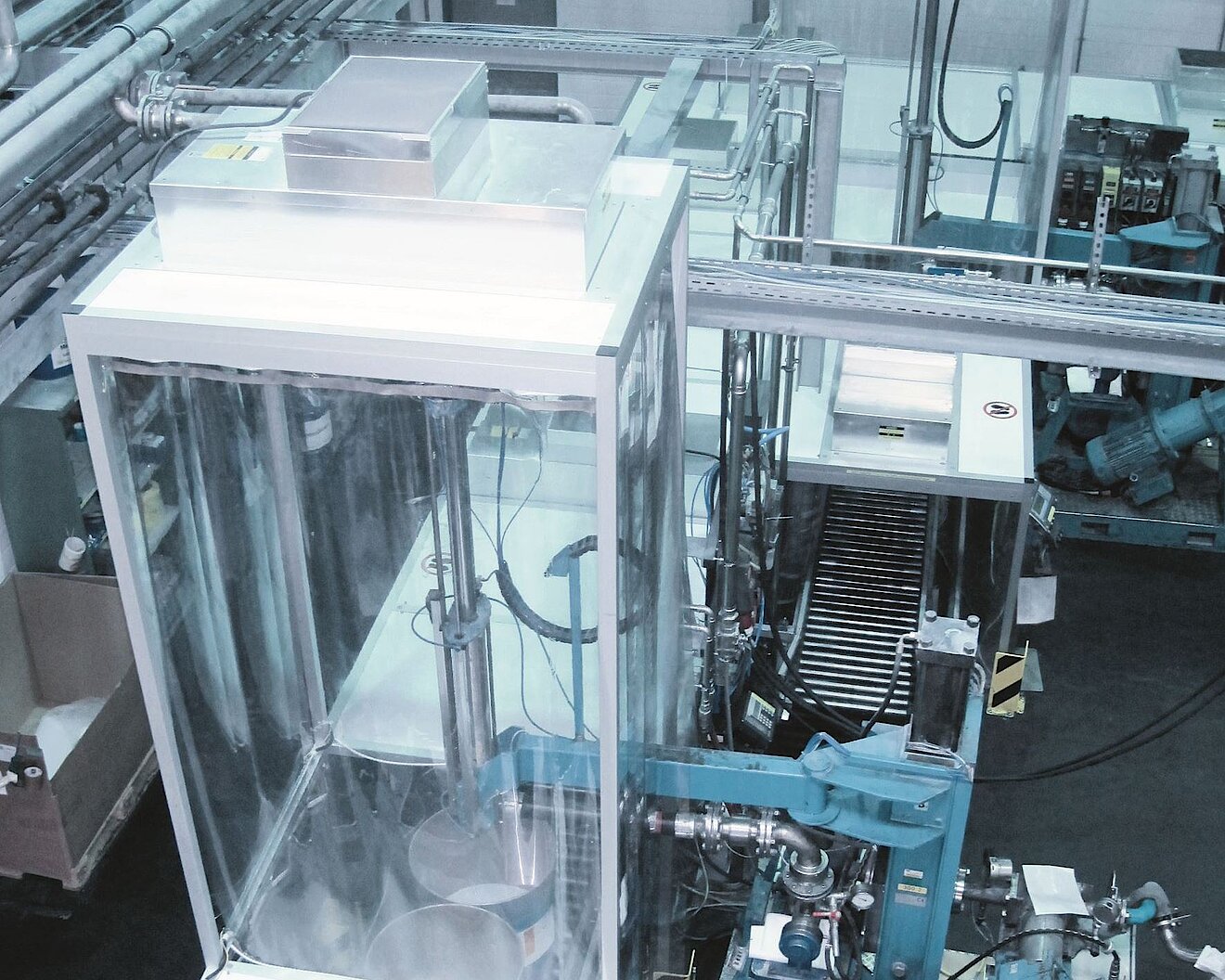

Smaller cleanroom enclosures are often sufficient for production machines and for the general production environment in order to control air flows and particle distribution within certain processes. Our customized machine enclosures spatially delimit defined clean air areas. Whether enclosed with PVC film curtains or solid walls, our laminar flow module can be flexibly adapted to the size of your machines and conveyor systems.

A custom-made machine enclosure enables you to achieve a uniform and targeted air flow. Our high-performance filter systems displace impure air from the process. They reduce the particle concentration to a minimum and effectively prevent the contamination of sensitive products.

Cleanroom space is very expensive. With targeted laminar flow, we create a clean environment in the smallest of spaces with our machine housings and attachments.

Our machine housings, which are equipped with laminar flow modules, offer considerable advantages in sensitive production environments. These enclosures ensure that clean air is directed into the work area through a controlled, laminar flow. This effectively removes particles and impurities from the air, which significantly improves production quality.

A particular advantage of this cleanroom box is that it is a cost-effective solution for creating small, ultra-clean areas without the need for large cleanroom areas. This is particularly beneficial in industries such as medical technology, electronics manufacturing and pharmaceuticals, where any contamination can have serious consequences.

Our machine enclosures and attachments are individually adapted to your machine for each project. In this way, we ensure that the enclosures correspond exactly to the dimensions and special features of your machines. This not only enables efficient use of the available space, but also ensures that the laminar flow functions optimally and that maximum cleanliness is achieved in the work area. This is the only way we can create a safe process environment.

Our machine enclosures are suitable for automated processes that require a particle-free environment. The laminar flow modules integrated into the enclosures ensure controlled air quality and prevent contamination.

Examples of applications where SCHILLING ENGINEERING has installed machine enclosures with laminar flow modules include

- Plastic injection molding

- Medical component manufacturing

- Packaging of medicines

- Infusion bag production

- Production of blood plasma bags

- Automated micro injection molding

- Hollow blow molding machines

- Ophthalmologic surgery

Laminar flow modules equipped with ULPA 15 filters are installed in our machine enclosures. The targeted laminar air flow and the separation from the unclean area by flexible PVC curtains or fixed walls create ideal cleanroom conditions.

This cleanroom box generates a uniform and controlled air flow thanks to the integrated laminar flow module. Particles are removed from the work area and a clean environment is ensured. Our ULPA 15 filters filter 99.9995% of particles down to 0.12 micrometers in size from the air, ensuring extremely high air purity. The flexible PVC curtains or fixed walls create a physical barrier that clearly separates the cleanroom area from the unclean area, minimizing contamination.

Our machine enclosures can replace a cleanroom in some cases, especially if only certain production areas require a controlled environment. These cleanroom boxes are equipped with laminar flow modules that generate a targeted, laminar air flow. This achieves a high level of air purity that is even better than the conditions in a cleanroom.

The cleanroom box is therefore an efficient solution as it shields only the required area, saving your company the cost and space of large cleanroom areas. However, it is important to emphasize that the cleanroom box is not suitable for every application.