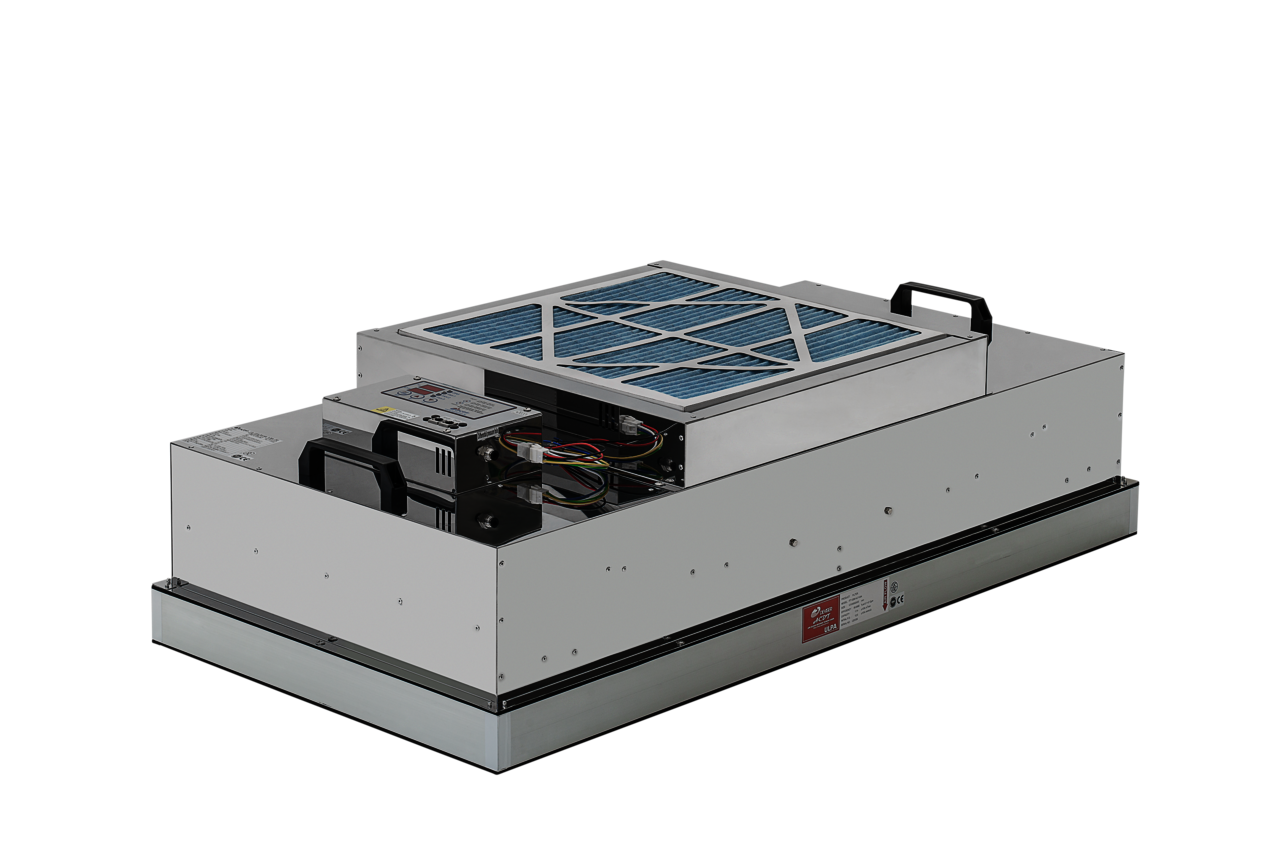

FFU ULPA 15

Typ SGE-EC

1210 x 600 x 335 mm

& individual sizes

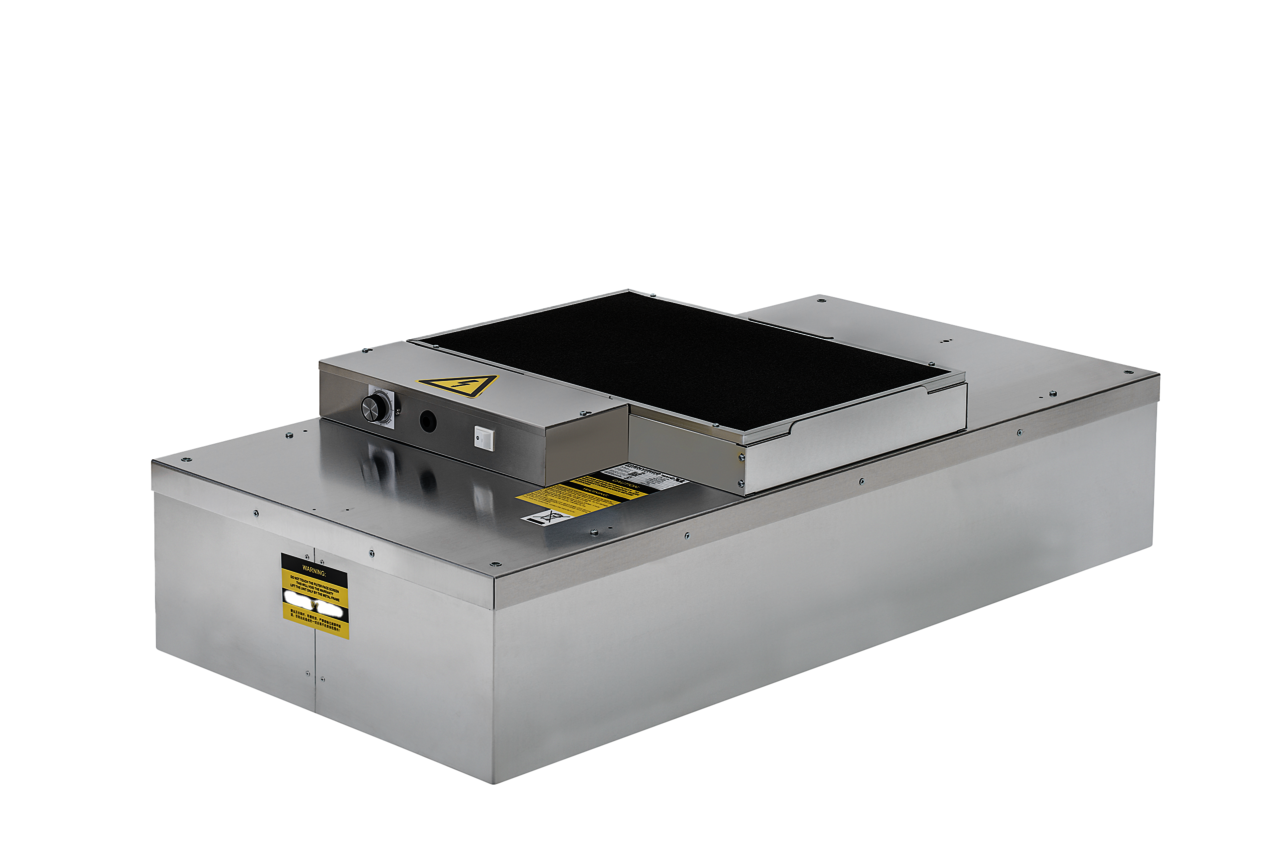

FFU ULPA 15

ENVIRCO - MAC10

1210 x 600 x 320 mm

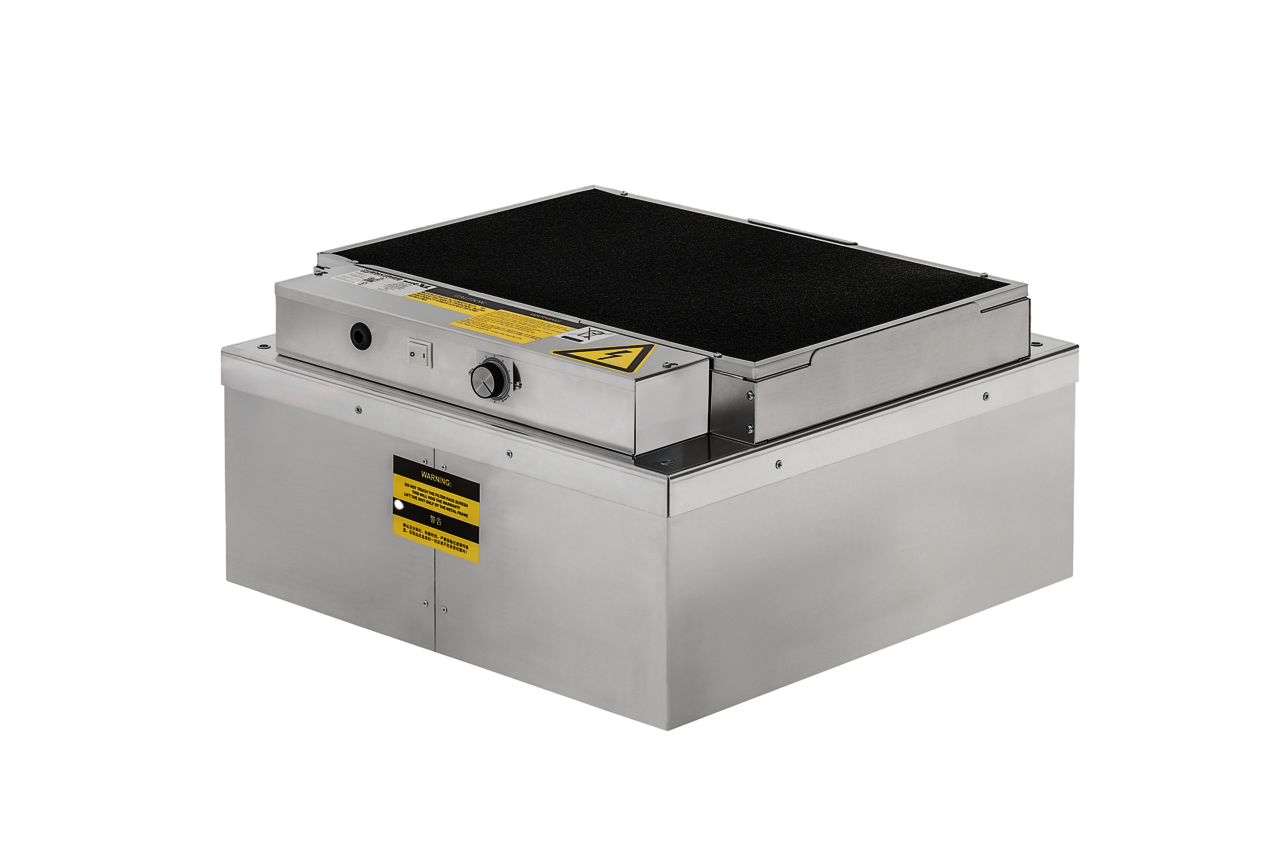

FFU ULPA 15

ENVIRCO - MAC10

600 x 600 x 320 mm

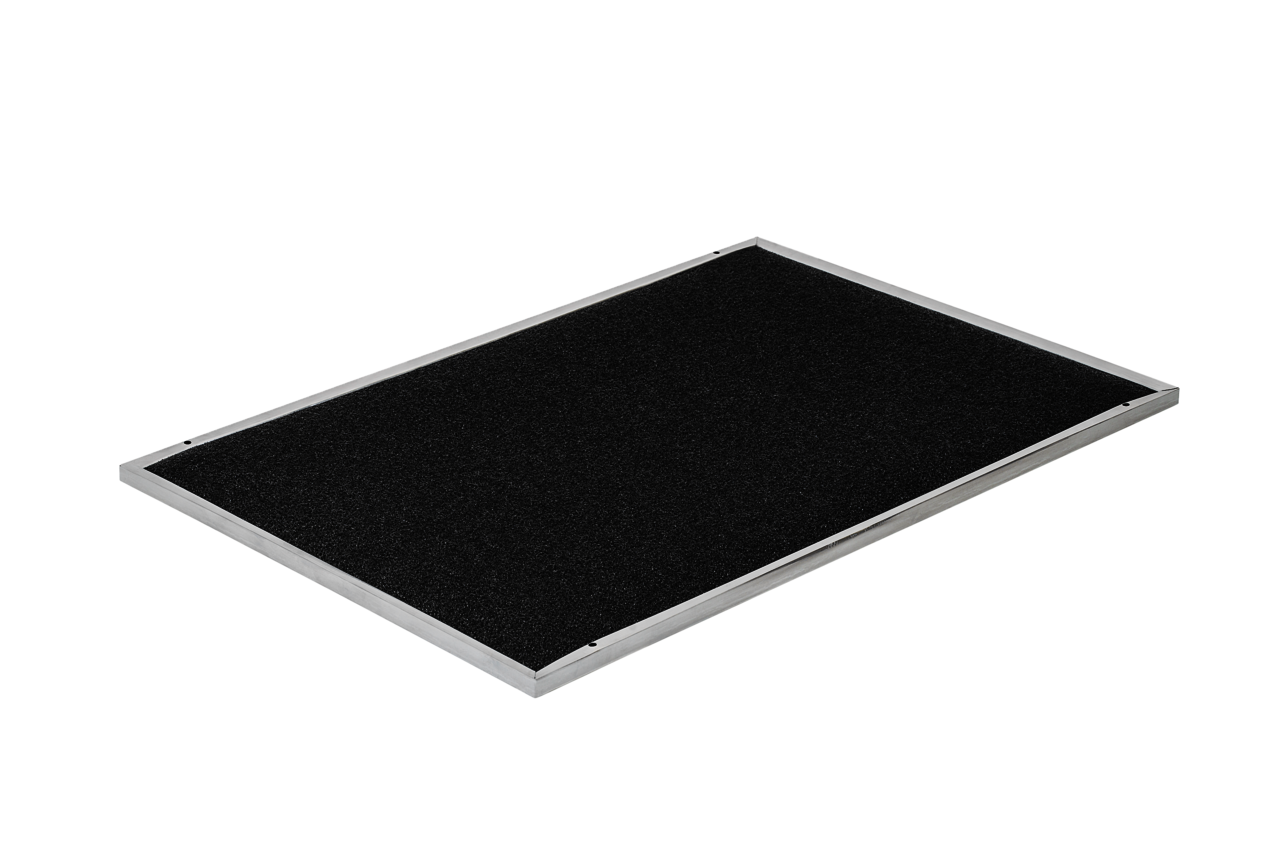

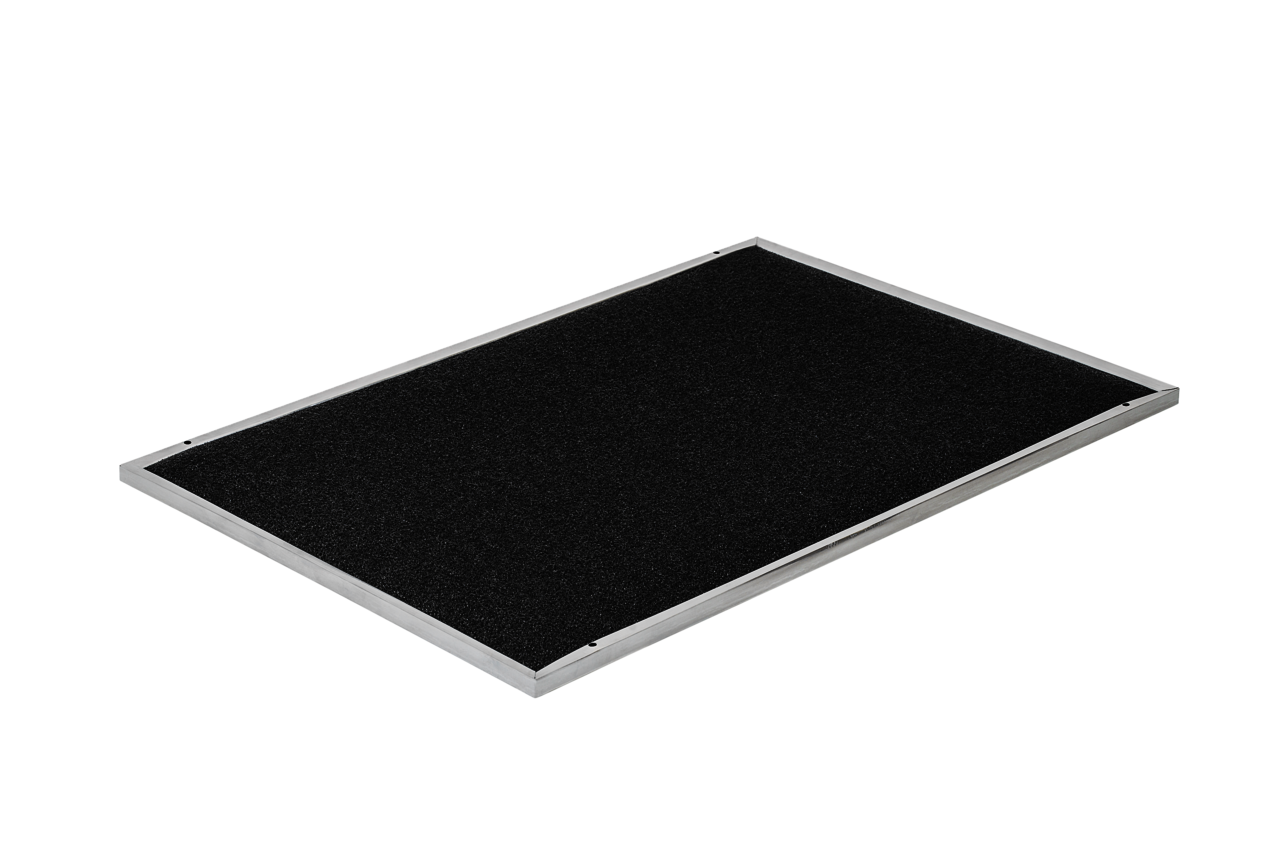

Replacement filter ULPA 15

Typ SGE-EC

1210 x 600 mm

Replacement filter ULPA 15

ENVIRCO - MAC10

1210 x 600mm

Replacement filter ULPA 15

ENVIRCO - MAC10

600 x 600mm

Pre-filter for FFU

Typ SGE-EC

Pre-filter for FFU

ENVIRCO - MAC10

What is an FFU?

An FFU consists of a high-performance filter and an integrated fan. It draws in the air of the environment and releases filtered air in a defined clean quality. The highly pure filtered air is thus free of particles such as dust, bacteria, aerosols, germs or even pollen. The air flows through the cleanroom via a laminar flow with a corresponding air velocity and carries airborne particles with it. The air flow rate is specified in cubic metres per hour (m³/ h) and describes how many cubic metres of room air can be circulated per hour.

Which application are the FFU suitable for?

Schilling Engineering's FFUs are integrated into the ceiling of

- cleanrooms,

- cleanroom tents and

- CNC cleanrooms to save space.

If the filters need to be serviced or replaced, easy access from below is possible. The air filter unit also ensures targeted cleanliness in our workplaces and enclosures. Each FFU from Schilling Engineering is equipped with a high-performance ULPA 15 filter, which precisely filters even the smallest particles from the ambient air with a separation efficiency of 99.9995 %.

What are the advantages of an FFU?

With our air filter units, you increase safety when manufacturing sensitive products or products in your cleanroom laboratory. Adapted to your requirements, absolute purity can be permanently guaranteed by the filter fan unit. With a central control system, you can operate the clean air filters and coordinate the general conditions required for you in your clean room. To sum up, you have the following advantages:

- High particle retention capacity

- High power density

- Absolut purity permanently guaranteed

- Optimized flow characteristics

- Quiet operation

- Easy to use

- Easy to control

- Increased efficiency