- Cleanroom classes ISO 5 - 9 and GMP B, C, D

- Modular and flexible cleanroom construction

- Self-supporting basic structure

- Fully integrated air circulation walls

- Doors with LED visualisation

- Airlock concepts with furnishing

- Central control and monitoring system

- Energy-optimised system with air-conditioning technology

- Installation including qualification

- Turnkey handover

Cleanroom solutions for industrial production

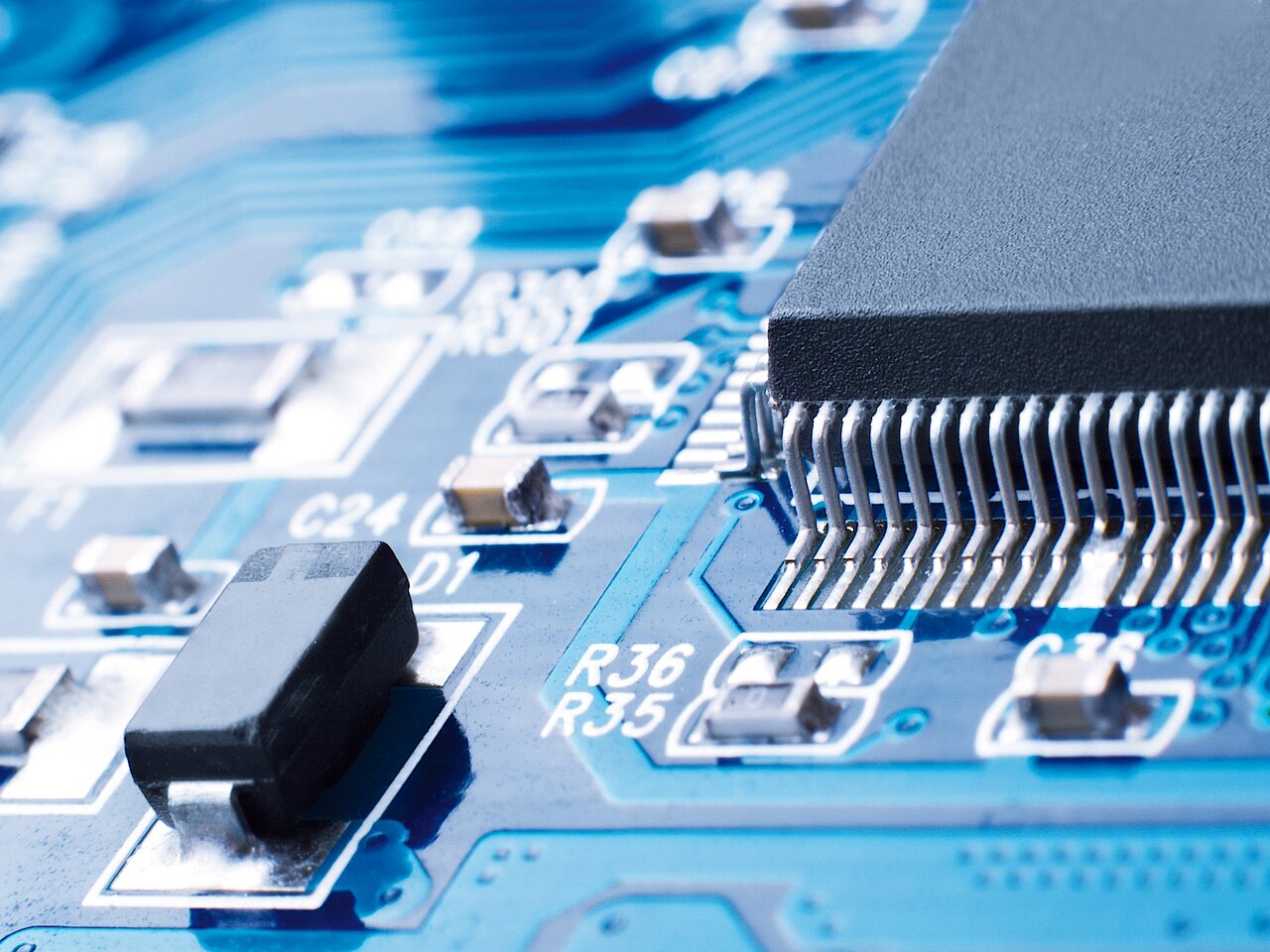

A large number of sensitive products in the high-tech industry can only be manufactured under cleanroom conditions. Our CleanCell4.0 cleanroom solution is used where even the smallest impurities endanger industrial production. With modern control technology, the cleanrooms meet the requirements of cleanroom classes ISO 5 to ISO 9. The systems are suitable for high-tech areas of electronics, the semiconductor industry, microtechnology, optics and much more.

Medical cleanroom solutions

Products intended for the medical sector have particularly high quality and hygiene requirements. We recommend our CleanMediCell medical cleanroom for use in the particularly sensitive area of medical technology with ISO classes 5 - 8. They provide extra safety with special seals and increased filter performance. For contamination-free plastics production, our laminar flow attachments and special conveyor technology complement a controlled and automated process of injection moulding or hollow blow moulding production.

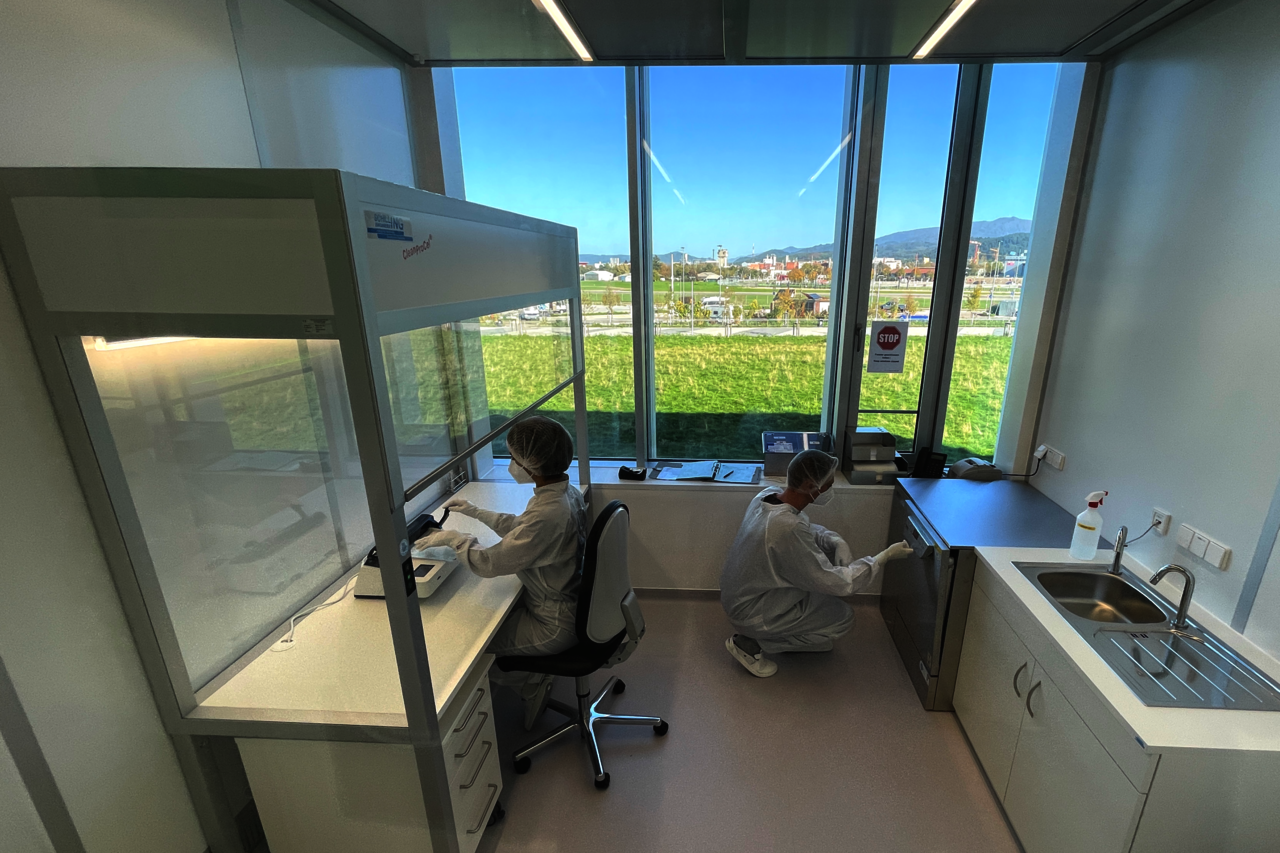

Cleanroom laboratory for germ-free processes

In the demanding areas of pharmaceutical processing, in laboratories and pharmacies, the requirements for cleanrooms are particularly high. The cleanroom laboratory CleanSteriCell guarantees compliance with the strict legal standards for product and personal protection. Our cleanroom laboratories comply with GMP cleanroom classes B, C and D and prevent contamination by germs, spores and microbiological contamination. Our cleanrooms are also used for germ-free processes in food technology and cosmetics.

Simply put, a clean room is a closed space into which virtually dust- and germ-free air is admitted via a filter system. In a cleanroom, clean air displaces airborne particles, keeps them away from objects with targeted air flows, and carries them to the outside. The number of particles per cubic meter of air determines the quality of the cleanroom.

The definition of a cleanroom is therefore concerned with the particle concentration of the ambient air, which must be reduced to a low, non-critical level. The controlled elimination of the harmful influence of particles and microorganisms ensures significantly higher quality and safety. Many processes can only be carried out under cleanroom conditions.

Basically, there are three goals to be achieved with a cleanroom:

1. product protection

- Ensuring the quality and function of sensitive products

- Protection against contamination by germs and microorganisms

2. personal protection

- Protection of employees in case of leakage of toxic substances

- Protection of employees from germs and microorganisms

3. environmental protection (clean rooms with negative pressure)

- Hazardous / toxic substances do not escape to the outside

- Dust remains in a closed room

In many cases, individual protection goals can be met by simple measures. A smaller enclosure, an exhaust system, etc. However, as soon as a combination of objectives becomes necessary, the whole thing starts to become more elaborate. A very striking example is the production of cytostatics. Drugs that are needed for cancer therapy. Here, all three goals must be met at once. The product must be manufactured in a sterile state, and people and the environment must be protected from the substances. In addition to a safety cabinet, this also requires a high-quality and safe clean room laboratory or sterile laboratory.

The term cleanroom system describes the composition of various components for keeping a specific environment clean. Similar to a work process, each component fulfils a specific task so that absolute cleanliness is permanently guaranteed. A cleanroom system includes, for example:

- Monitoring elements: These show how many particles there are per m³ of air in the cleanroom and warn you in good time as soon as a certain limit is exceeded. Our precise measuring devices ensure absolute cleanliness at all times.

- Filtration systems: They transport "dirty air" outside, while the clean air remains in the cleanroom.

- Cleanroom plenary: This cleanroom ceiling connects different components of the cleanroom system with each other and, above all, ensures a smooth return air flow. They convey impure air out of the building.

- Doors, windows, airlocks: Our high-quality equipment ensures trouble-free work in the cleanroom as well as consistently high cleanroom air quality.

- Cleanroom furniture: The cleanroom equipment supports efficient work within the cleanroom.

- Cleanroom technology: For all cleanroom systems, we provide high-class cleanroom technology to ensure safe and effective working processes.

Every square metre of cleanroom space is expensive to build, and even more so to operate. Specifying a larger area or a higher cleanroom class ultimately means more filter systems, more "air", more cost.

The first questions we usually ask our customers are therefore

Are you sure you need this cleanroom class?

Are you sure you need this cleanroom size?

Are you sure you need air conditioning, especially humidity control?

In addition to investment, energy costs play a significant role in question 3. That's why we explicitly focus on energy-efficient solutions. It is only by understanding the process that we can help the customer to avoid unnecessary costs for cleanroom technology and not to use a sledgehammer to crack a nut. The goal is maximum customer benefit, not maximum sales.

It doesn't always have to be a permanently installed cleanroom, but an enclosure or cleanroom tent is often sufficient for manual activities - for example in combination with a laminar flow bench. For clean production, a cleanroom or combination with laminar flow benches may even be sufficient. In some cases, the cleanliness of the controlled environment can be achieved without the need for a cleanroom. For mechanical processes, machines can be installed and encapsulated outside the cleanroom. In this case, wall openings or conveyor belts are used to access the cleanroom. There are many ways to reduce costs without compromising safety.

So how much cleanroom do you need? - As much as necessary and as little as possible.

This is the one question that our sales people are asked very often and often right at the beginning of a project enquiry.

To be honest, we can't really give a concrete answer to the price of a cleanroom in an initial phone call. And not because we don't stand behind our prices or want to hide anything. Quite the opposite. But simply because a whole range of information has to reach us before we can offer solutions for cleanroom production - often at different prices. When asked about the costs of a cleanroom, a serious salesperson must always reply with "It depends".

That's why we have a whole series of counter-questions:

- What cleanroom class is needed?

- How big and how high should the room be?

- Can the ceiling be suspended or should it be free-standing?

- Is air conditioning required?

- What heat loads will be generated?

- Are there GMP specifications?

- How many people will be working in the cleanroom?

These are just some of the parameters that flow into a calculation. Because a cleanroom is not an off-the-shelf product. It must be precisely tailored to the cleanliness requirements and the needs of production.

Only then can we decide together with our customers whether, metaphorically speaking, a Porsche is necessary or whether a Polo will suffice.

But just to satisfy your curiosity for a moment:

A cleanroom costs between 1,000 and 5,000 euros per square metre.

For a cleanroom classification, air samples are taken at various points in the room with a particle counter and it is measured how many particles are found. Based on these measurements, the classification of the purity of the room is carried out. The classification in cleanroom classes describes the pollution of the room atmosphere by particles of different sizes per room volume. The cleanroom standard is qualified according to a cleanroom class table.

How are clean rooms differentiated?

- Cleanrooms are differentiated according to their type of classification. In ISO cleanrooms, the main focus is on removing airborne particles that must not be deposited on sensitive products. In GMP cleanrooms, microbiological contamination via germs and spores must also be prevented.

- The cleanroom classifications according to ISO standard 14644-1 or according to the GMP guideline Annex 1 determine the overall design of the cleanroom. The more sensitive the processes, the stricter the cleanroom cleanliness requirements. Cleanroom classes range from ISO 1- ISO 9 and from GMP A- D, with lower numbers indicating higher particle removal standards.

Depending on the cleanroom class, the air of the cleanroom must be completely exchanged with varying frequency. This is done via laminar air flows that carry clean air into the cleanroom and force airborne particles out of the cleanroom.

The classification for which industry a cleanroom class is suitable differs depending on the process and requirement. Therefore, the required cleanroom class is determined individually for each cleanroom so that the requirements for the subsequent process are met exactly. Typical areas of application per cleanroom class are:

- ISO 8 cleanroom class for the automotive industry

- ISO 7 cleanroom class for medical technology

- ISO 6 cleanroom class for the optical industry

- ISO 5 cleanroom class for electronics and semiconductor technology

But also here applies: it always depends on the specific process and the requirements for the purity of the end product. A general classification per sector cannot be made!